Services

Consulting

We can serve anyone who needs support in the following directions:

- to choose the right PVD deposition technology for thin films deposition;

- to choose the best suited deposition equipment, even from another supplier;

- to choose the best suited pumping unit, based on the chosen deposition technology, substrate material and batch capacity;

- to help in designing or doing custom design of arc evaporation cathodes with magnetic steering of the cathode spot velocity and trajectory;

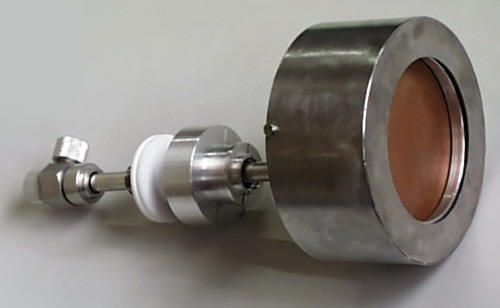

- to help in designing or doing custom design of planar magnetron cathodes for flange mounting or fully immersed in vacuum, choosing the right magnetic array configuration depending on the application, etc.;

- to choose or design the most appropriate substrate holders and transport or planetary motion systems, depending on the chosen deposition technology and equipment;

- to do preliminary calculations of the production costs based on the chosen equipment and deposition technology;

- to make projects for upgrade of existing PVD systems for increasing the capacity or quality of deposited coatings, change of deposition technology, etc.

We are experts in the field of thermal evaporation, cathodic arc evaporation and magnetron sputtering, including the reactive processes. We have thirty years of experience in the reactive film deposition by PVD and in particular more than thirteen years in the field of deposition of hard, wear resistant coatings. Based on this experience we can assist our customers in choosing best suited complex coatings depending on its application – decorative coatings onto plastics or glass, optical coatings onto variety of substrate materials, EMI shielding coatings, coatings for cutting or forming tools, etc.

↑ UpSystems and Products Design

Design of new products, systems and technologies in the field of vacuum measurement and thin film deposition technologies. We are eager to collaborate with organizations in similar fields of activity to develop new projects. Two of our newest products in the field of vacuum measurement - Absolute Membrane Vacuum Gauge AMVG 01 and Active Pirani Transmitter and Controller were developed on behalf of and in cooperation with companies operating in the Laser Industry.

We are open to collaborate to develop new projects in the field of measurement, Data Acquisition Systems or Discrete Process Automation. Our few years of experience in the field of singlechip microcontrollers and mixed signal microcontroller solutions, used also in our vacuum gauges and controllers, will be advantageous.

↑ Up

Reconstruction

Renovation and reconstruction of used vacuum equipment and systems for thin film deposition, based on thermal evaporation, cathodic arc evaporation, triode cathode sputtering and magnetron sputtering, including reactive sputtering or evaporation. We can inspire new life on your old High Vacuum System, not supporting your recent requirements and needs.

Development of technologies for thin film deposition and multilayer coatings, especially designed to satisfy different customer's requirements, including decorative and wear resistant multilayer coatings on customer site. Coatinsg onto glass, metal and plastics substrates, including 3D coating.

Delivery of used pumps, valves and fittings, technological equipment and High Vacuum Systems by customer's request.

↑ Up

Learn more about our dual channel Pirani Vacuum Gauge

Learn more about our dual channel Pirani Vacuum Gauge Learn More about our planar magnetron cathodes

Learn More about our planar magnetron cathodes Learn More about our power supplies

Learn More about our power supplies